Stay Ahead with MOVUS Insights! Get the latest updates, tips, and industry news delivered straight to your inbox.

Solutions / Technology

Easy to install, simple to use, and powerful enough to optimise your operations and reduce downtime.

FitMachine: Condition Monitoring Made Easy

FitMachine provides continuous condition monitoring by tracking vibration, noise, and temperature in real time. It detects subtle changes in asset behaviour, helping you address issues early before they escalate.

Key Features:

FitPower: Driven Condition Monitoring

FitPower tracks your equipment’s energy consumption patterns, providing unique insights into asset condition. By identifying abnormal power usage, it helps you detect inefficiencies and emerging issues before they impact operations.

Key Features:

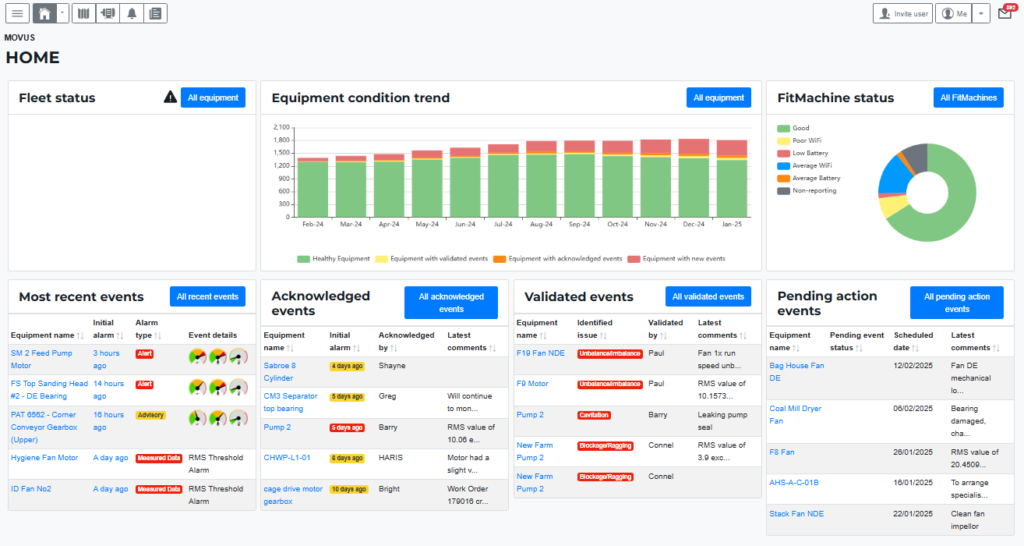

MachineCloud: Simplified Insights

MachineCloud brings all your monitoring data together into one user-friendly dashboard. Designed for simplicity, it provides clear insights so you can make informed decisions quickly.

Key Features:

Centralised dashboard for real-time asset data.

Customisable features to prioritise high-risk assets.

Accessible from anywhere for remote monitoring.

Seamless Integration with Your Systems

MOVUS technology makes it easy to integrate the data we capture into your existing systems. Whether through APIs, data streaming, or webhooks, you can seamlessly incorporate actionable insights into your workflows and tools.

Key Features:

How It All Works Together

Our tools work together to provide a complete picture of your assets. From detecting anomalies through vibration and energy to managing equipment health via a unified dashboard, MOVUS technology ensures your operations are always running at their best.

Seamless integration between devices and dashboard.

Real-time data for proactive decision-making.

Minimal setup and maintenance.

MOVUS condition monitoring gives you the power to avoid unplanned downtime, take preventative action and reduce the risk to your people on the ground.

© MOVUS Australia Pty Ltd

ABN 91 612 415 611

Contact MOVUS today to discuss a condition monitoring package tailored to support your critical assets and end-to-end operations.

Sign up for the MOVUS newsletter and stay informed on how to maximise uptime and reduce unplanned failures.