Stay Ahead with MOVUS Insights! Get the latest updates, tips, and industry news delivered straight to your inbox.

FitMachine

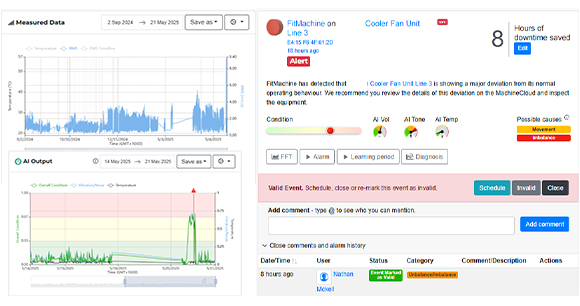

| Scenario | Downtime Avoided | Estimated Cost Avoided |

|---|---|---|

| Minimum | 2 hours | AUD $5,000 |

| Likely | 8 hours (official) | AUD $20,000 |

| Maximum | 24 hours | AUD $60,000 |

MOVUS condition monitoring gives you the power to avoid unplanned downtime, take preventative action and reduce the risk to your people on the ground.

© MOVUS Australia Pty Ltd

ABN 91 612 415 611

Sign up for the MOVUS newsletter and stay informed on how to maximise uptime and reduce unplanned failures.

Contact MOVUS today to discuss a condition monitoring package tailored to support your critical assets and end-to-end operations.